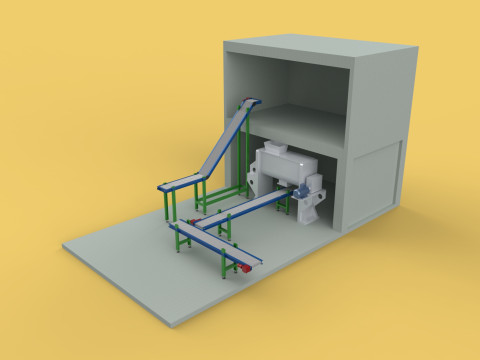

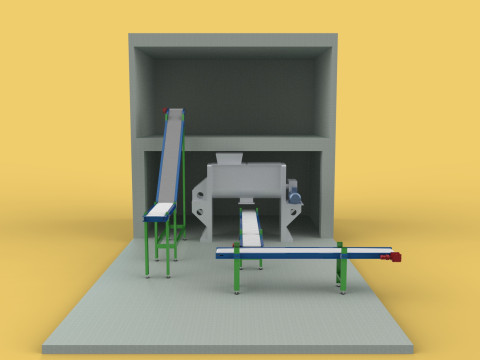

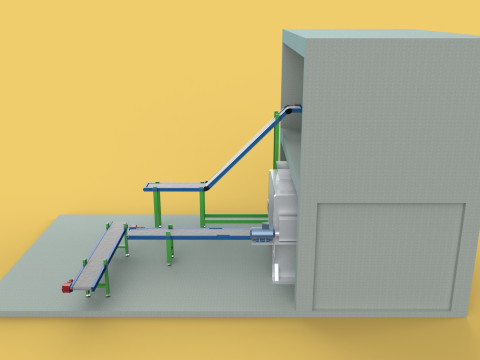

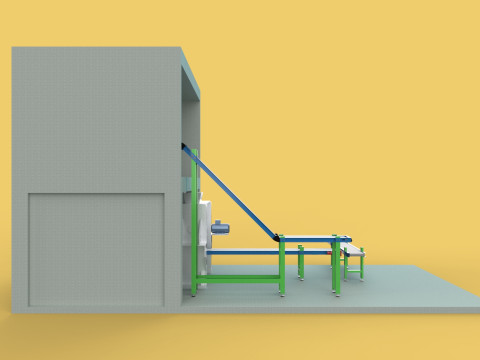

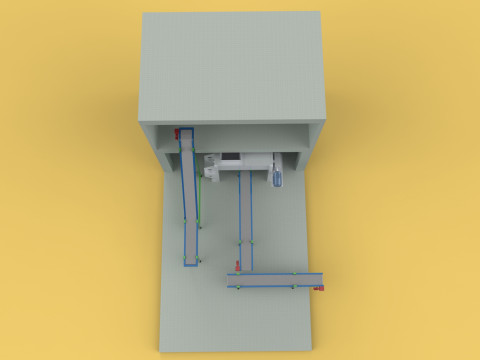

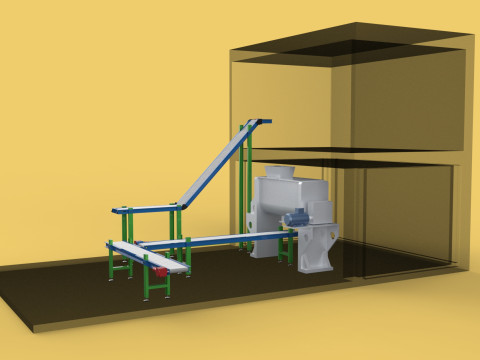

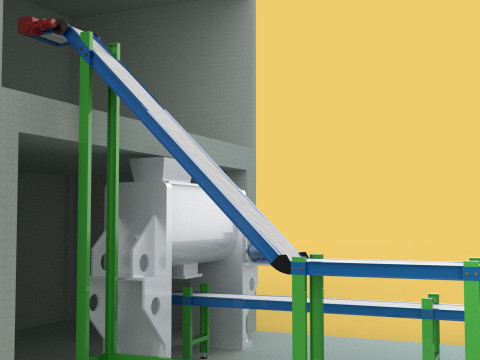

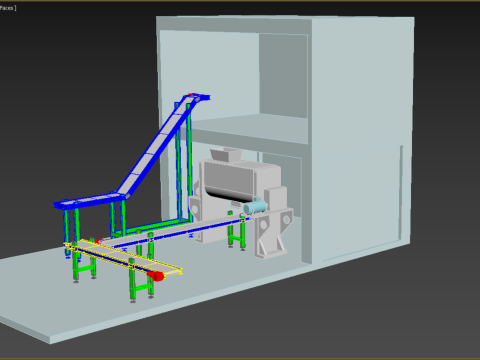

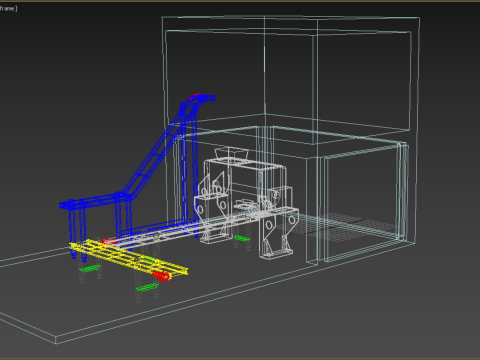

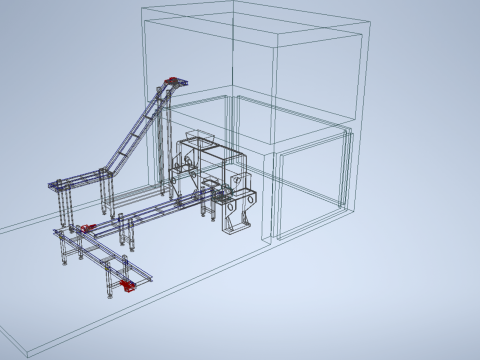

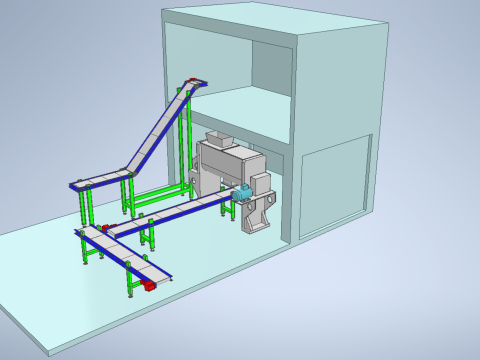

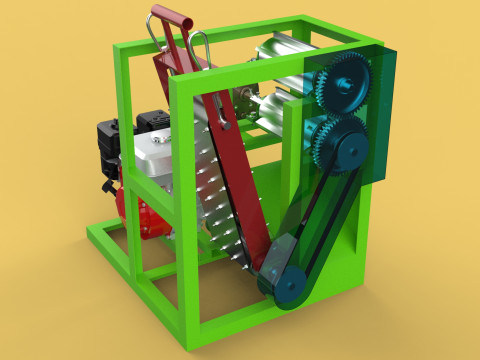

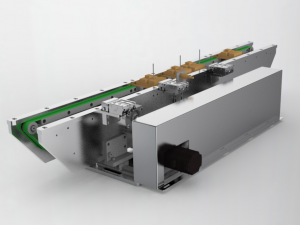

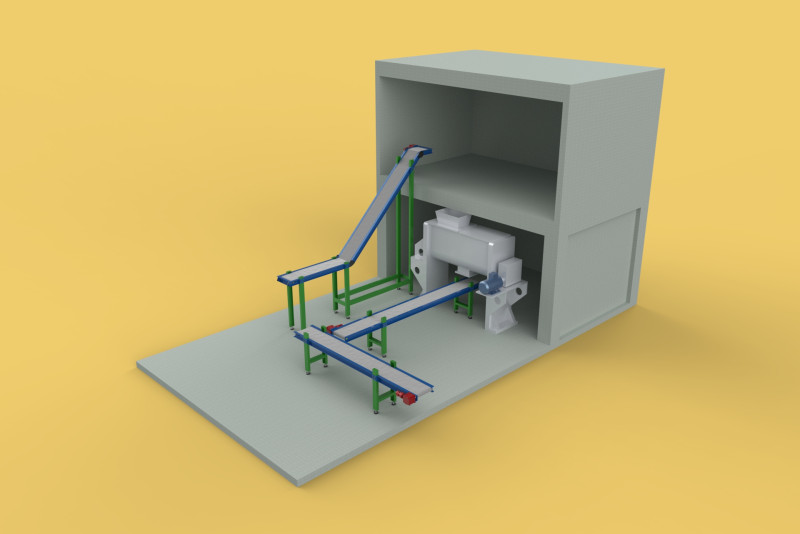

BELT CONVEYOR RIBBON MIXER BLENDER PRODUCTION LINE WAREHOUSE

Modello 3D

- Formati disponibili: Rhinoceros: 3dm 1.71 MB3DS MAX all ver.: 3ds 295.82 kbBlender: blend 1.33 MBAutoCAD (native): dwg 1.54 MBAutodesk FBX: fbx 919.62 kbIGES: iges 471.57 kb3DS MAX: max 2.18 MBWavefront OBJ: obj 677.15 kbACIS: sat 704.92 kbSketchUp: skp 2.09 MBStereolithography: stl 650.79 kbSTEP: step 318.65 kb

- Pligoni:60931

- Vertici:60019

- Animato:No

- Textured:No

- Rigged:No

- Materiali:

- Low-poly:No

- Collezione:No

- Mapping UVW:No

- Plugins Utilizzati:No

- Stampa Pronta:No

- 3D Scan:No

- Per adulti:No

- PBR:No

- AI Formazione:No

- Geometria:Poly NURBS

- UVs Aperti:Unknown

- Visualizzazioni:922

- Data: 2024-11-02

- ID Oggetto:538898

- Voto:

The model contains the most popular formats:

1. 3DS MAX: *.max

2. Blender: *.blend

3. Rhinoceros: *.3dm

4. SketchUp: *.skp

5. Wavefront OBJ: *.obj *.mtl (Multi Format)

6. FBX: *.fbx (Multi Format)

7. STEP: *.step *.stp (NURBS)

8. IGES: *.iges *.igs (NURBS)

9. ACIS: *.sat (NURBS)

10. 3DS MAX all ver.: *.3ds (Multi Format)

11. Stereolithography: *.stl

12. AutoCAD: *.dwg

- Each file was checked for opening and full content by the model.

- The 3D model was created on real base. It’s created accurately, in real units of measurement, qualitatively and maximally close to the original.

- Renders Are made in Luxion Keyshot

- “WE PROVIDE 3D MODEL CHEAP PRICE BUT WITH GOOD QUALITY”

- If you need any other formats we are more than happy to make them for you. Contact me for any question :)

Sincerely Your, SURF3D

MORE INFORMATION ABOUT 3D MODELS :

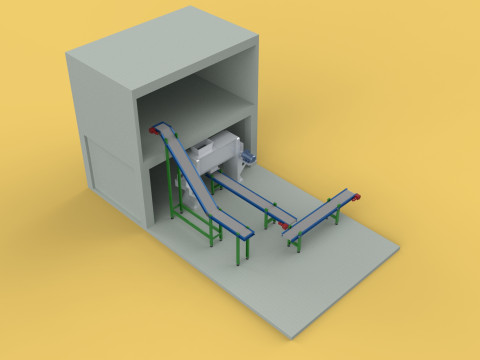

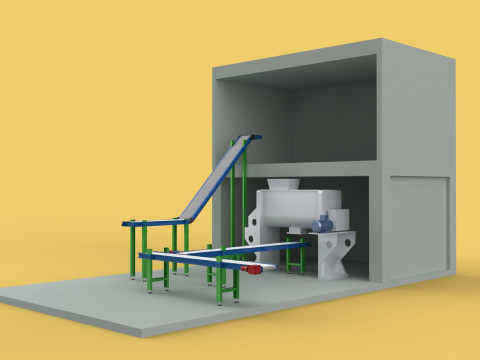

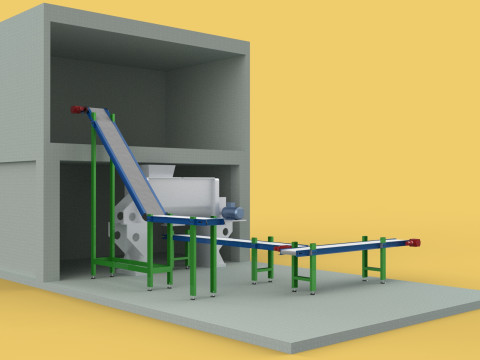

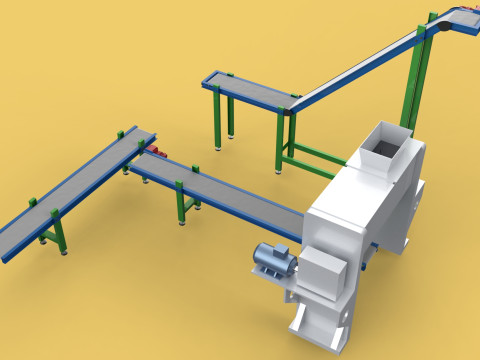

Belt conveyors, ribbon mixers, and blenders can all be integrated into a production line within a warehouse to automate and streamline material handling processes. Here's how they might work together:

Scenario: A warehouse that manufactures or packages dry ingredients for food products.

Ingredients Infeed: Bulk ingredients like flour, sugar, or grains arrive at the warehouse in sacks or bulk containers. They are unloaded and fed onto a belt conveyor.

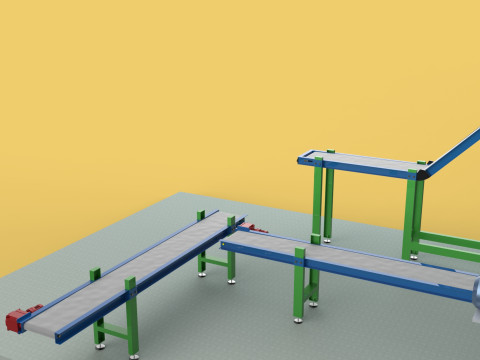

Belt Conveyor Transfer: The belt conveyor transports the ingredients horizontally or at a slight incline to the blending area.

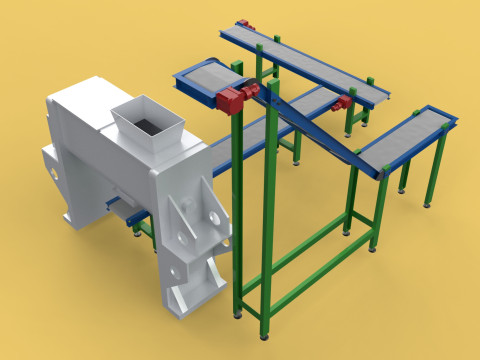

Ribbon Mixer/Blender: The conveyor discharges the ingredients into a ribbon mixer or blender. These machines use a horizontal, U-shaped trough with a rotating internal ribbon that lifts, folds, and tumbles the materials to ensure uniform mixing.

Blended Product Discharge: Once mixed, the blended product exits the mixer and may be deposited onto another belt conveyor for further transport.

Packaging or Storage: The conveyor transfers the blended ingredients to a packaging station or storage silos, depending on the final product and production flow.

Benefits of this Integration:

Automation: Reduces manual labor required for moving and mixing materials.

Efficiency: Faster and more consistent movement of materials throughout the production line.

Accuracy: Ribbon mixers ensure precise and homogenous blending of ingredients.

Reduced Risk of Contamination: Minimizes manual handling, reducing the potential for foreign object contamination.

Other Considerations:

Conveyor Capacity: The belt conveyor's capacity should be sufficient to handle the required material flow rate.

Mixer Size: The size and type of ribbon mixer will depend on the volume and specific types of ingredients being blended.

Dust Control: If the dry ingredients generate dust, a dust collection system might be necessary to prevent air quality issues within the warehouse.

By combining belt conveyors, ribbon mixers, and blenders, warehouses can achieve a more automated and efficient production line for blending dry ingredients.

Se hai bisogno di diversi formati, aprire un nuovo Ticket i Supporto e una richiesta per questo. Convertiamo modelli 3D a: .stl, .c4d, .obj, .fbx, .ma/.mb, .3ds, .3dm, .dxf/.dwg, .max. .blend, .skp, .glb. Non convertiamo scene 3d e formati come .step, .iges, .stp, .sldprt.!

English

English Español

Español Deutsch

Deutsch 日本語

日本語 Polska

Polska Français

Français 中國

中國 한국의

한국의 Українська

Українська Italiano

Italiano Nederlands

Nederlands Türkçe

Türkçe Português

Português Bahasa Indonesia

Bahasa Indonesia Русский

Русский हिंदी

हिंदी